Integration: PTC Windchill and EPLAN

The upcoming launch in May 2015 is based on the strategic cooperation between EPLAN and PTC.

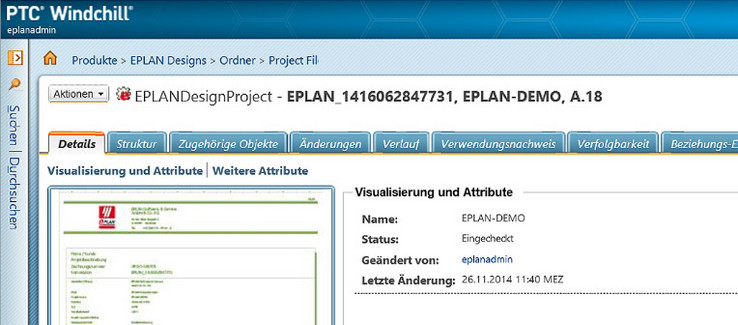

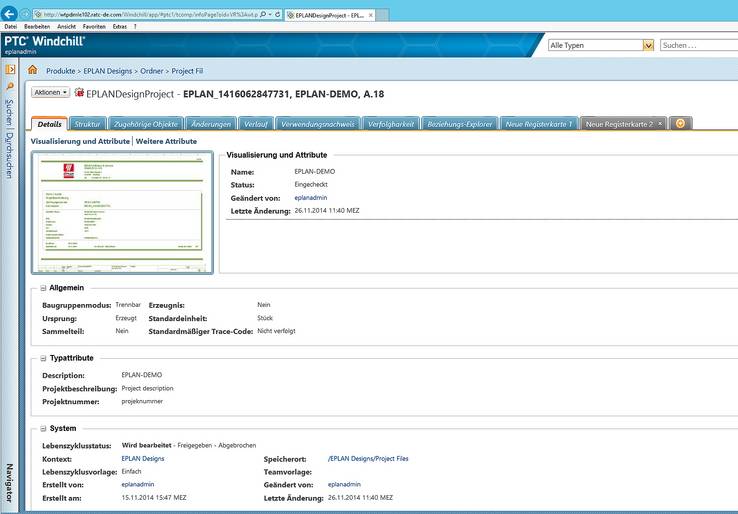

At this year’s Hannover Messe, solutions provider EPLAN presents its new Windchill connector. The upcoming launch in May 2015 is based on the strategic cooperation between EPLAN and PTC. Their common goal: integrated mechatronic solutions by embedding CAE in PDM/PLM. Monheim, 07 April 2015 – Product data management with PTC Windchill, engineering with EPLAN: this opens up new and effective pathways and optimisation potential. With the new Windchill connector, EPLAN delivers an interface to manage EPLAN datasets in PDMLink, the PTC Windchill PDM system. The connector, availaible in May 2015, combines two market-leading solutions and sets the course for integrated product lifecycle management through to mechatronics. Bernd Schewior, Senior Vice President Professional Services at EPLAN, explains: “We received initial binding customer queries even in the early concept phase. There’s a huge amount of interest because we and PTC have a fairly strong common customer base, and the mechatronic perspective remains trendsetting.” The common goal for this integration is supporting the interdisciplinary product development processes that unite PTC and EPLAN. A cooperation based on trust and an orientation towards added value for common clients was confirmed last year in November 2014 when EPLAN became a PTC Gold Partner.

Integration: Features & Functions

The integration covers key requirements in the area of design data management. These include design data management for EPLAN data; opening, saving and revising; support for all approval and change processes; generating and updating of EPLAN evaluations; bi-direction synchronization of project attributes; creating, saving and revising EPLAN parts lists in PTC Windchill; and authenticating EPLAN users and permission assignments in the PTC Windchill environment. The integration of PTC Windchill functionality into the EPLAN interface allows users to conveniently access the PDM system from their customary working environment. Integrated data flows ensure transparency and support cooperation between various disciplines. The integrated exchange of information between commercial production, engineering and manufacturing represents an additional leap forward in increasing efficiencies. Common customers benefit from closely coordinated developments in the area of integration. EPLAN Software & Service, April 2015